AUGUR Т

Automated ultrasonic inspection system for austenitic and pearlite welded joints of large thickness using traditional ultrasonic transducers and TOFD technology

AUGUR-T system with the ability to connect up to eight pairs of ultrasonic piezoelectric transducers and a diffraction-time control method (TOFD).

The system has been successfully tested in "Rosenergoatom" Concern, "Gazprom".

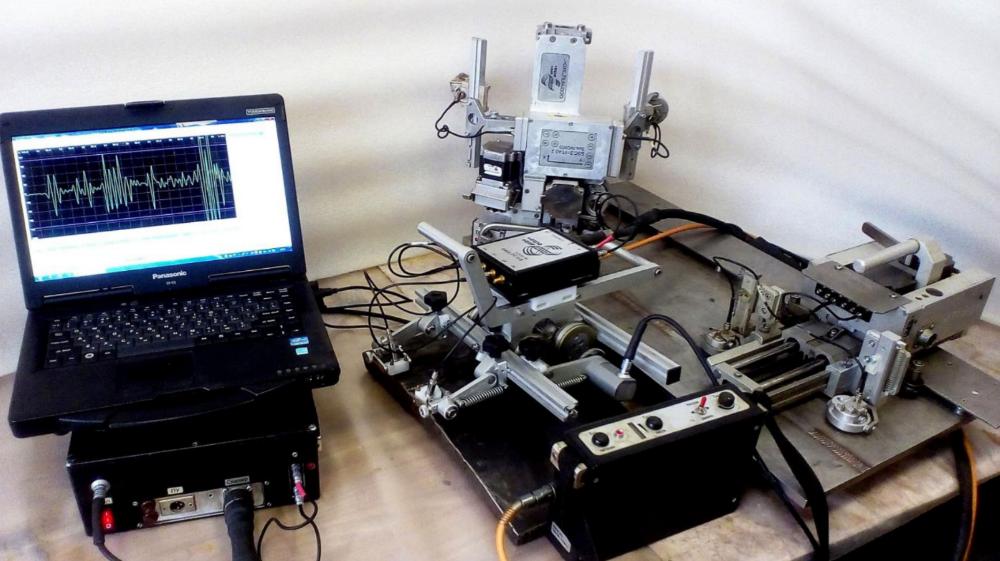

AUGUR-T system unit with control computer and scanning devices

- Automated Ultrasonic Inspection

- Up to 14 independent channels

- Without blower

- IP54 protection

- Control speed up to 80 mm/s

- Easy integration

- Three operating modes: express control mode, search control, measuring control

The AUGUR-T system provides:

- support for acoustic holography and TOFD modes;

- detection and visualization of defects, determination of their sizes and coordinates;

- carrying out automated control of products up to 500 mm thick;

- multifunctional program for registration and analysis of control results.

Standard equipment*

- System unit (article D0160010)

- Ethernet cable (article D0160011)

- Power supply unit (article D0160012)

- Power cable 60 m (article D0160013)

- Scanner connection cable (article D0160014)

- Control computer**

- Packaging

**The view of the control computer may differ from the photo

AUGUR T is operated in conjunction with the following scanning devices.

Scanner СК426T4

Article S0160122

- The range of inspection pipe diameters is from 426 mm to the plane

- Included are longitudinal and transverse tracks for various pipe diameters (from Ø426 mm to the plane) and local tracks

Scanner 426T

Article S0160086

- The range of inspection pipe diameters is from 426 mm to the plane

- The set includes longitudinal and annular tracks depending on the diameters of the inspection pipes

- Ring tracks can be set closed and local

- Inspection of austenitic and pearlite welded joints

- Operation in heavy industrial conditions

Scanner 219T

Article S0160087

- Диапазон контролируемых диаметров трубопроводов - от 219 мм до 800 мм

- В комплекте поставляются кольцевые трека в зависимости от диаметров контролируемых труб

- Кольцевые треки могут быть поставлены замкнутые и локальные

- Контроль аустенитных и перлитных сварных соединений

- Эксплуатация в тяжёлых промышленных условиях

Scanner 560

Article S0160088

- The diameter of the inspection pipelines is 560 mm.

- A ring track is included.

- Inspection of austenitic and pearlite welded joints.

- Operation in heavy industrial conditions

| Specifications |

Express inspection mode |

Search inspection mode |

Measuring inspection mode |

|

| Absolute sensitivity | until 70 dB | |||

| The limit of the permissible absolute error of measuring the ratio of signal amplitudes at the input of the receiving path | until 0,5 dB | until 0,5 dB | until 0,5 dB | |

| Duration of the time sweep | from 1600 μs | from 400 μs | from 400 μs | |

|

1600 mm | 400 mm | 400 mm | |

|

The bandwidth of the receiving path at the level of -3 dB |

0,6 - 10 MHz | 0,6 - 10 MHz | 0,6 - 10 MHz | |

|

The range of adjustment of the amplitude of the probing pulse |

25 - 250 V | 25 - 250 V | 25 - 250 V | |

|

Deviation of the input angle from the nominal value for a PEP with a central frequency of less than 2 MHz |

± 2° | |||

| Deviation of the input angle from the nominal value for a PEP with a central frequency of 2 MHz or more | ± 3° | |||

| Deviation of the central frequency of the PEP from the nominal value | ±10% | |||

| Continuous operation time during the inspection (without reducing the reliability of the inspection results) | 8 h | |||

| Average service life of the system | at least 5 years | |||

|

Operating conditions at operating temperature range (for system units) |

1 - 40 °С | |||

| Operating conditions at operating temperature range (except system units) | -30 ... +50 °С | |||

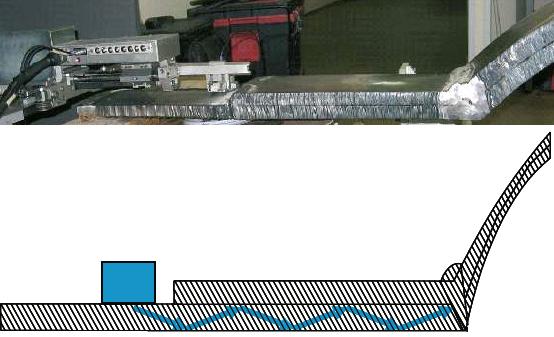

Automatic ultrasonic inspection of welded joints at a distance of up to 2 meters

-

Automatic ultrasonic inspection of welded joints of pipelines with diameters of 720-1420 mm

-

Inspection of welds at a distance of up to 2 m (multiple reflection from the walls of the pipe)

-

High inspection sensitivity

-

Inspection of seams with complex seam geometry

-

Changing the azimuthal angle of the acoustic axis direction

Automatic ultrasonic inspection of tees with an overlay

- Automated scanning along and across the pipeline axis in 120 mm by 150 mm zones

- Ultrasound insertion angle 70°

- At least three ultrasonic transducers with different azimuthal orientation (depends on the ratio of the diameters of the welded pipes)

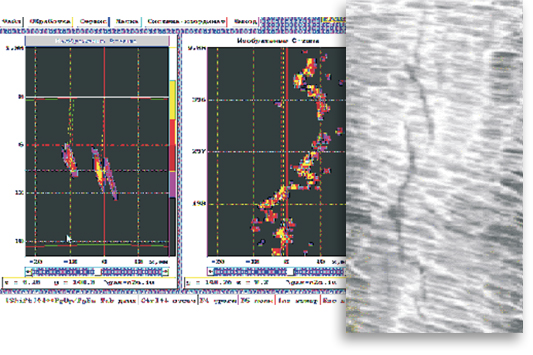

- Coherent processing (2D and 3D) to maximize sensitivity and resolution

Measuring mode of automatic ultrasonic inspection operation

- Application of coherent methods (acoustic holography)

- Determination of the actual size, type and orientation of defects

- Determination of the coordinates of the occurrence of discontinuities

- High inspection performance

- Holographic methods for obtaining three-dimensional images of defects

- Automated inspection, documentation, automatic formation of inspection conclusions, including in welded joints made of austenitic materials.