SERVICE & SUPPORT

- Automated ultrasonic inspection of welded joints of pipelines with measurement of the dimensions of defects and subsequent assessment of the residual resource of the object.

-

Automated ultrasonic control of pipeline welds during construction, repair and operation

-

Monitoring of the development of operational defects during the operation of facilities

-

Automated ultrasonic express control of the base metal and longitudinal welds of pipelines, for example, in the process of re-insulation and repair of gas pipelines

-

Inspection of oil and gas pipeline tees

-

Thickness measurement of vessels and pipelines for corrosion wear

-

Other types of non-destructive testing and diagnostics

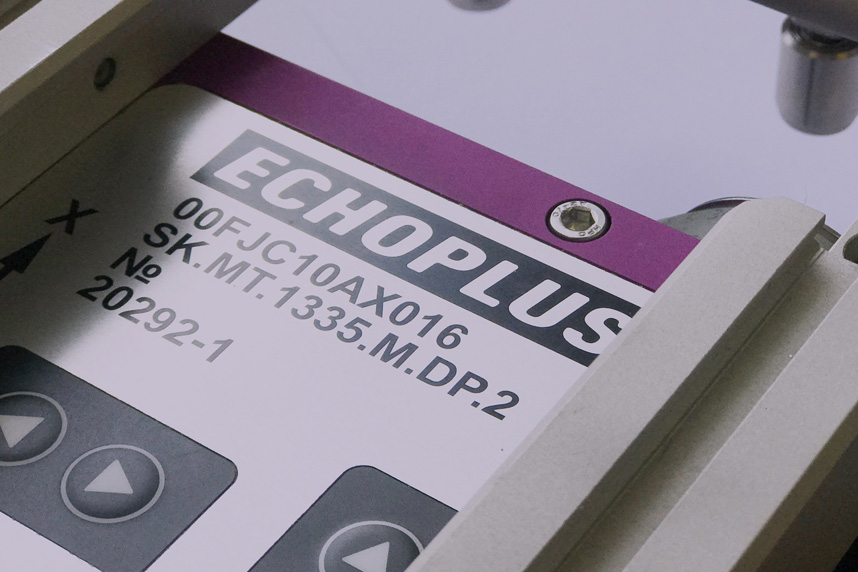

Each device of the SPC ECHOPLUS is born through the joint efforts of scientists, engineers and specialists. The list of products manufactured by the ECHOPLUS includes automated ultrasonic inspection systems, scanners, flaw detectors, phased array prisms, software.

All products and technologis of the ECHOPLUS are ready for integration into most technological processes related to safety at industrial facilities, or can be developed specially for the tasks of the customer.

Products>>

We will be happy to assist in the maintenance, as well as in further consulting and ordering products of the ECHOLUS Company. In case of repair or damage to the product, you can contact the technical department.

Work using the methods and products of ECHOLUS, as well as products of partner companies - Olympus and Sonatest, can be carried out by specialists working on the customer's side after finishing the recommended training course, which is included in the consulting services of ECHOLUS.

There are 4 Doctors of technical sciences and 3 candidates working at the ECHOLUS. Using the knowledge and experience of their employees, the teachers of the ECHOLUS Training Center train and certify specialists in the following areas:

- ultrasonic control on AUGUR 5.2 series devices;

- ultrasonic control by FR methods;

- methods of headlights on the automated ultrasonic inspection with AUGUR-ART, Omniscan, Harfang devices.

-

Monitoring the development of defects during the use of objects

- Justification for the replacement of X-ray control with automated ultrasonic inspection