30 December 2018

Ultrasonic inspection of welded joints of bridge metal structures

Tests of flaw detectors with phased arrays for the control of welded joints of bridge metal structures were carried out in the SPC ECHOPLUS.

1. GEKKO and AUGUR ART flaw detectors were used on butt, T-bar welded joints and welded joints of contact welding of Nelson stops.

2. The use of phased arrays in the digital focusing mode of the antenna in combination with scanning devices made it possible to identify defects at the required sensitivity level, to ensure 100% data recording.

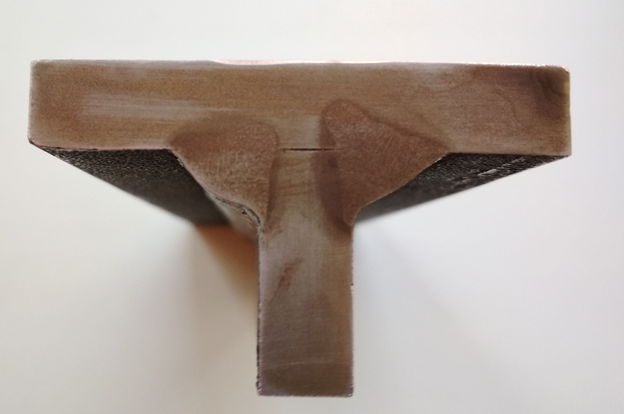

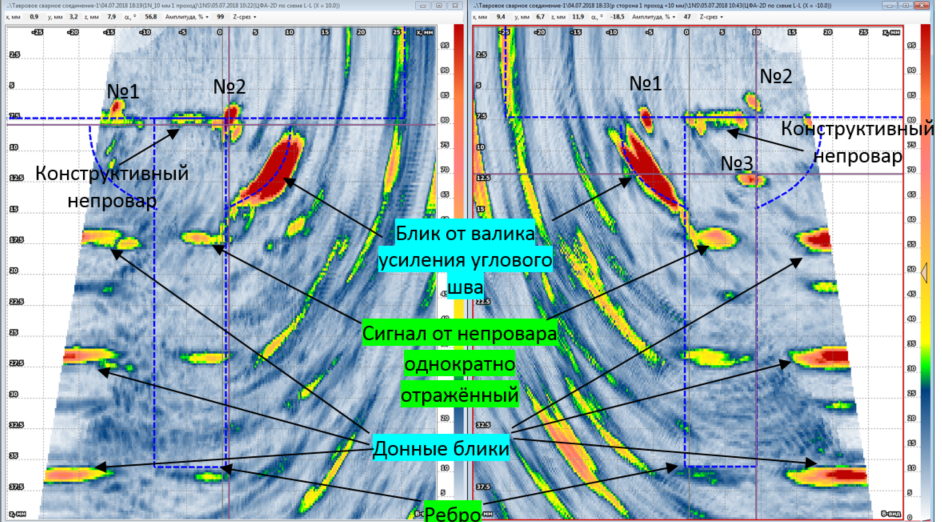

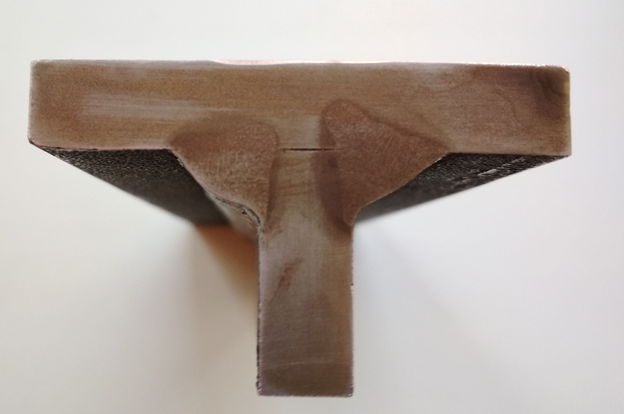

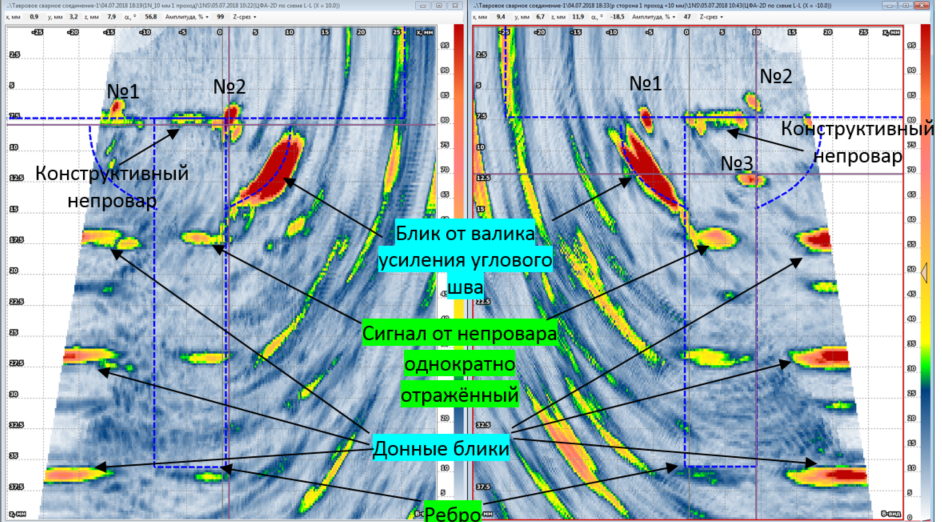

3. Models of defects in the form of lateral, flat-bottomed holes at the boundaries of fusion and in the deposited metal were revealed in the sample of a T-bar welded joint against the background of structural non-welding.

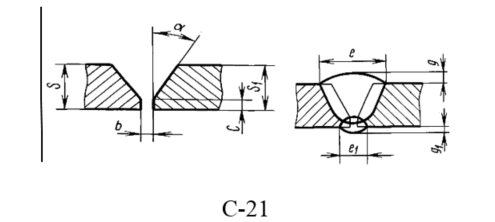

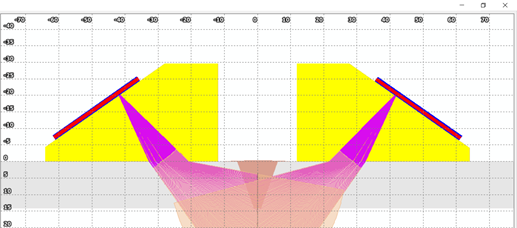

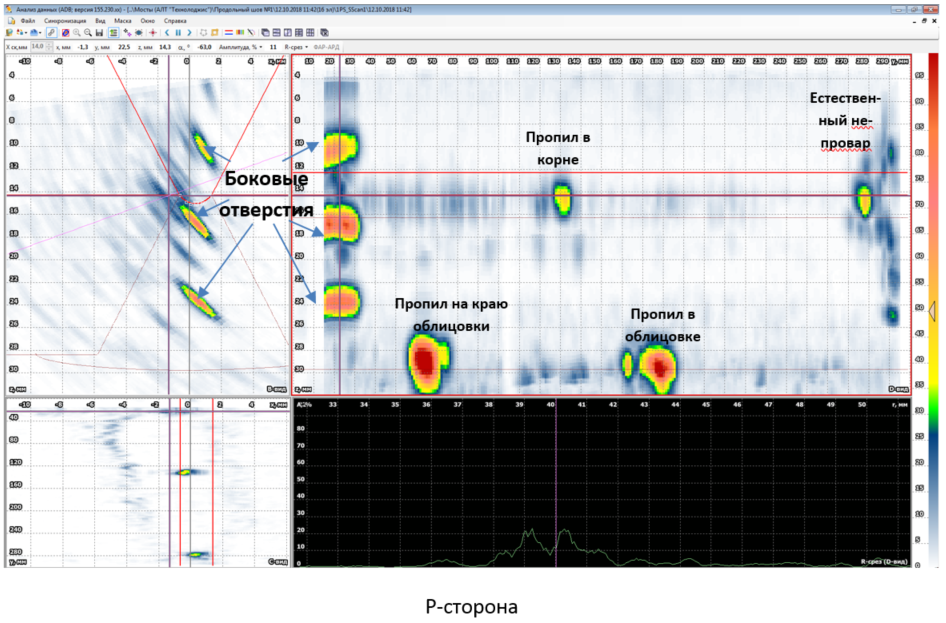

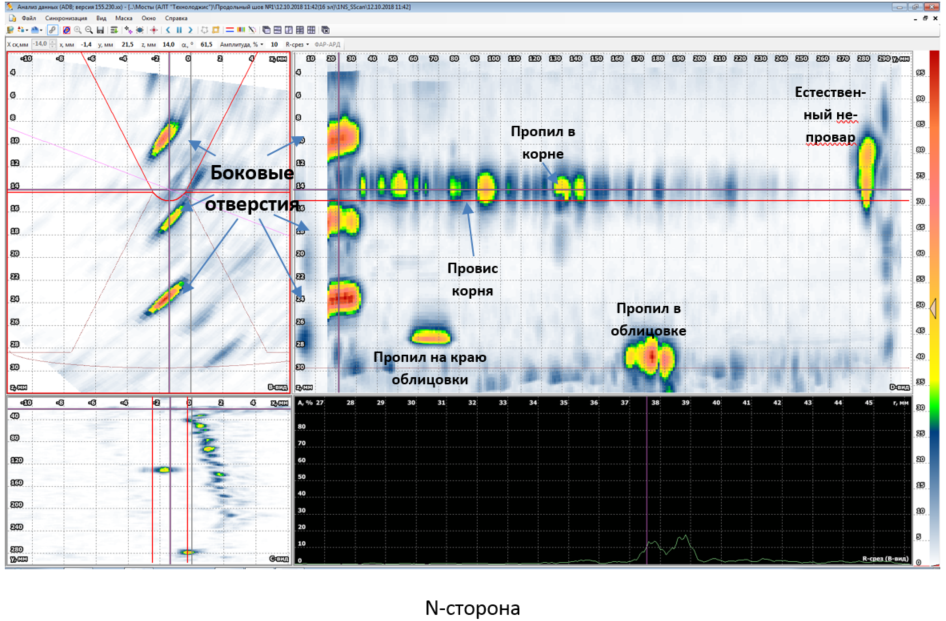

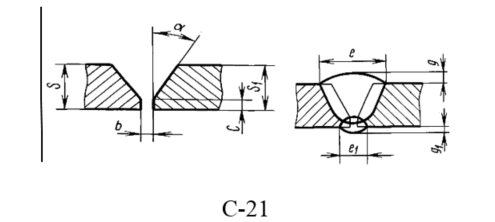

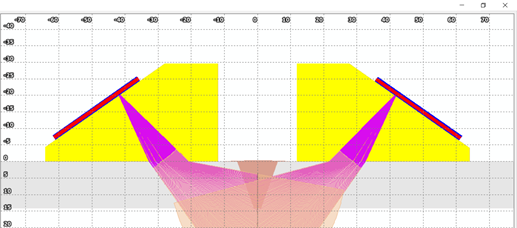

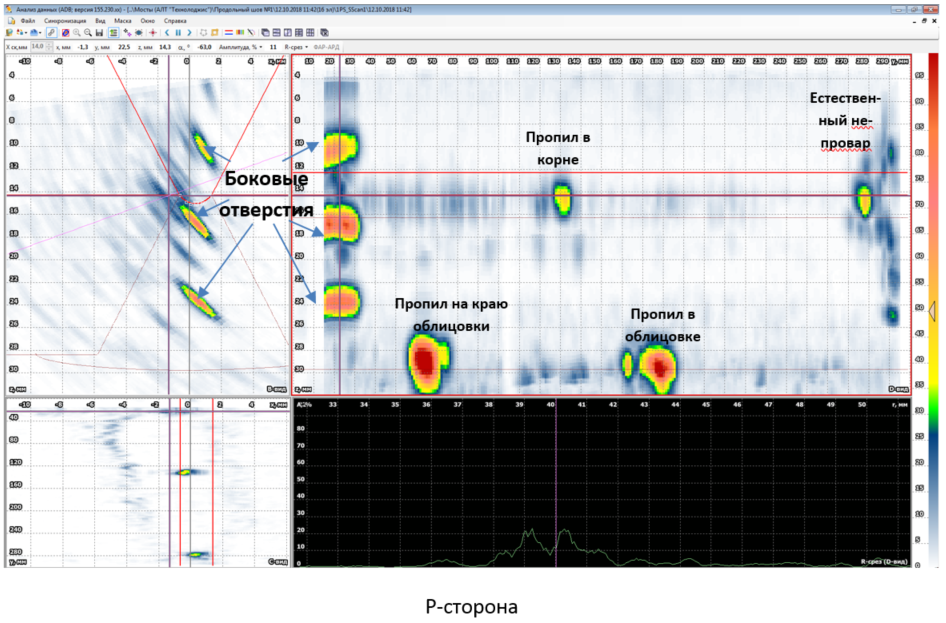

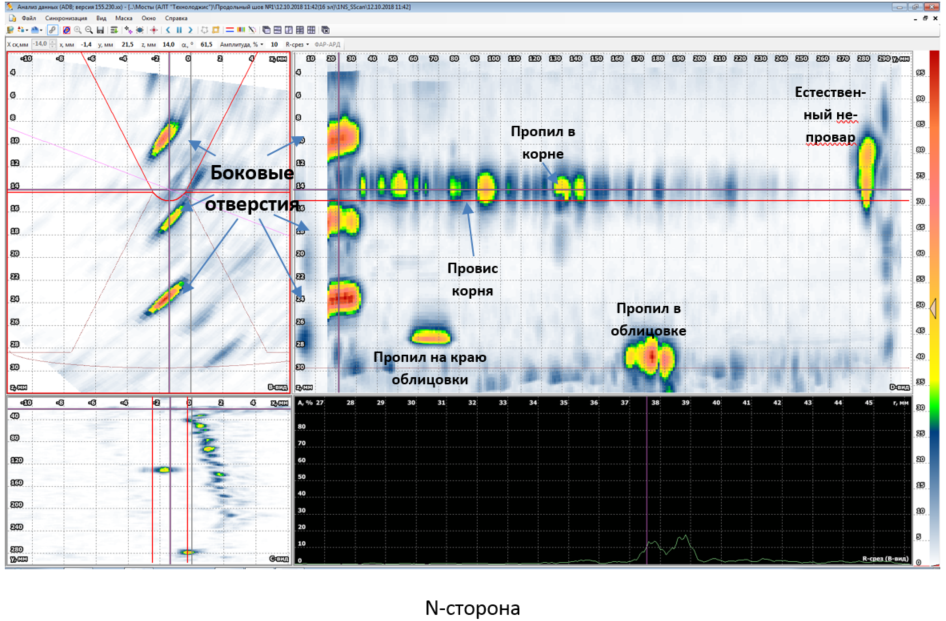

4. In butt welded joints with a thickness of 14 mm, obtained by automatic welding (cutting C-21), artificial defects were identified that mimic pressure cuts along the edges, at the root, undercuts. During the inspection, non-proofs and sagging of the root were also revealed. It is shown that it is preferable to use two phased arrays of the IM5M32E1P type (frequency 5 MHz, 32 elements, step between elements 1 mm).

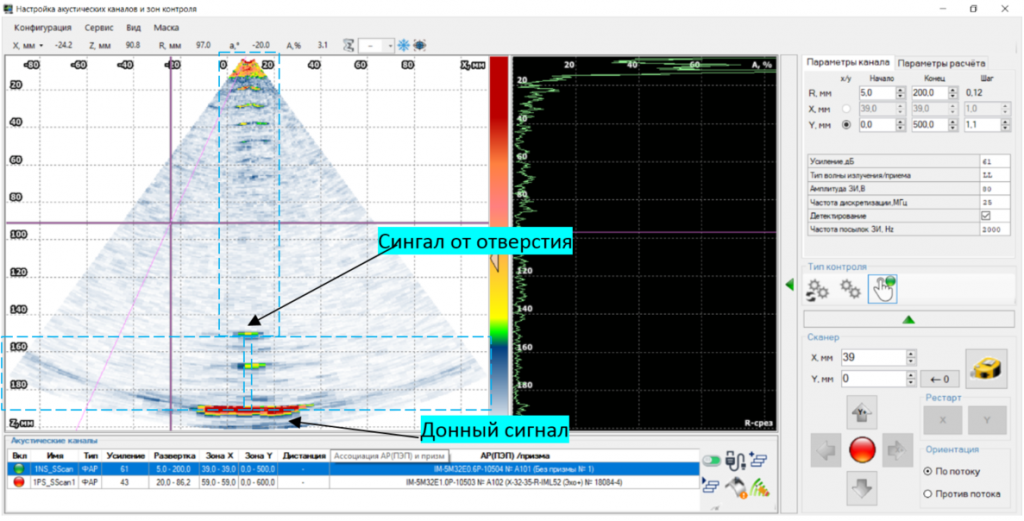

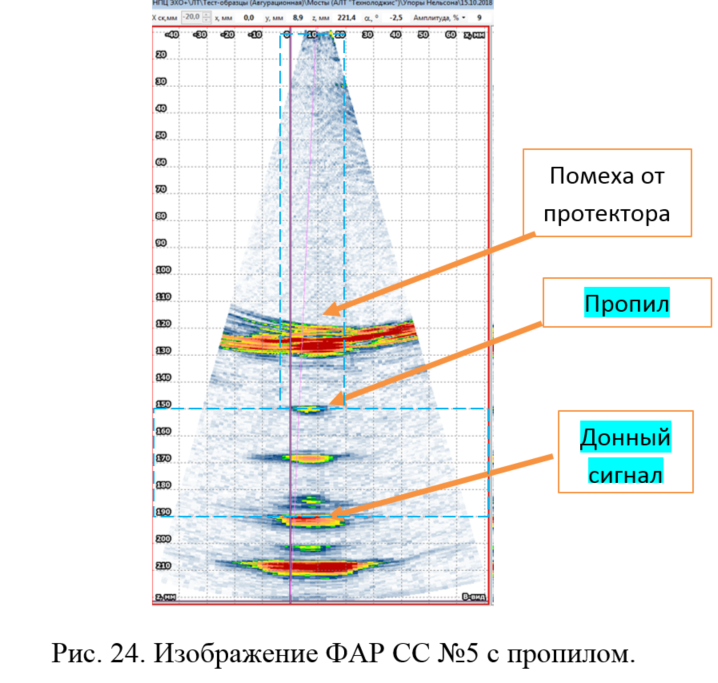

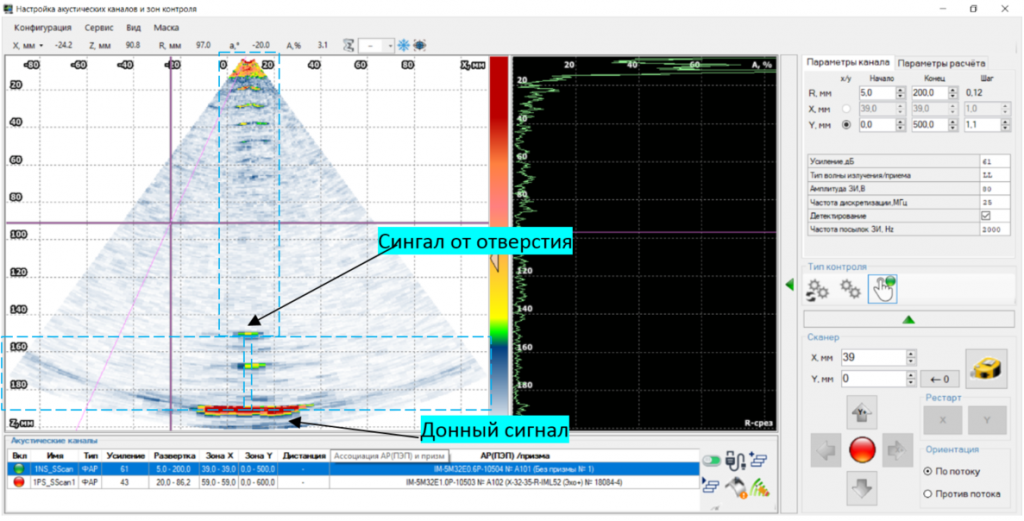

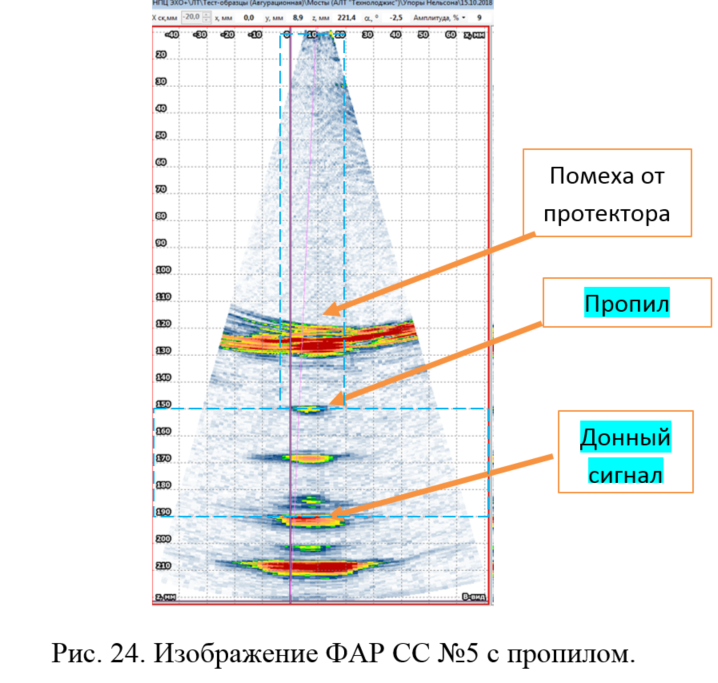

5. When checking the welded joints of Nelson stops, the possibilities of detecting defects in the contact welding zone when ultrasound is introduced from the "finger" side are shown. If it is impossible to eliminate irregularities on the contact surface of the "nickel", it is possible to use a flexible aquapolymer that fits the surface.

6. As a result of the measurements, conclusions were drawn about the suitability of controls using phased arrays (including those operating in the digital focusing mode of the antenna, CFA, TFM) for ultrasonic inspection of welded joints of bridge metal structures during production and during operation.

1. GEKKO and AUGUR ART flaw detectors were used on butt, T-bar welded joints and welded joints of contact welding of Nelson stops.

2. The use of phased arrays in the digital focusing mode of the antenna in combination with scanning devices made it possible to identify defects at the required sensitivity level, to ensure 100% data recording.

3. Models of defects in the form of lateral, flat-bottomed holes at the boundaries of fusion and in the deposited metal were revealed in the sample of a T-bar welded joint against the background of structural non-welding.

4. In butt welded joints with a thickness of 14 mm, obtained by automatic welding (cutting C-21), artificial defects were identified that mimic pressure cuts along the edges, at the root, undercuts. During the inspection, non-proofs and sagging of the root were also revealed. It is shown that it is preferable to use two phased arrays of the IM5M32E1P type (frequency 5 MHz, 32 elements, step between elements 1 mm).

5. When checking the welded joints of Nelson stops, the possibilities of detecting defects in the contact welding zone when ultrasound is introduced from the "finger" side are shown. If it is impossible to eliminate irregularities on the contact surface of the "nickel", it is possible to use a flexible aquapolymer that fits the surface.

6. As a result of the measurements, conclusions were drawn about the suitability of controls using phased arrays (including those operating in the digital focusing mode of the antenna, CFA, TFM) for ultrasonic inspection of welded joints of bridge metal structures during production and during operation.