25 December 2018

Report on the use of continuous thickness measurement tools on field gas pipelines

On November 7-10, 2018, tests of means for continuous ultrasonic thickness measurement were carried out.

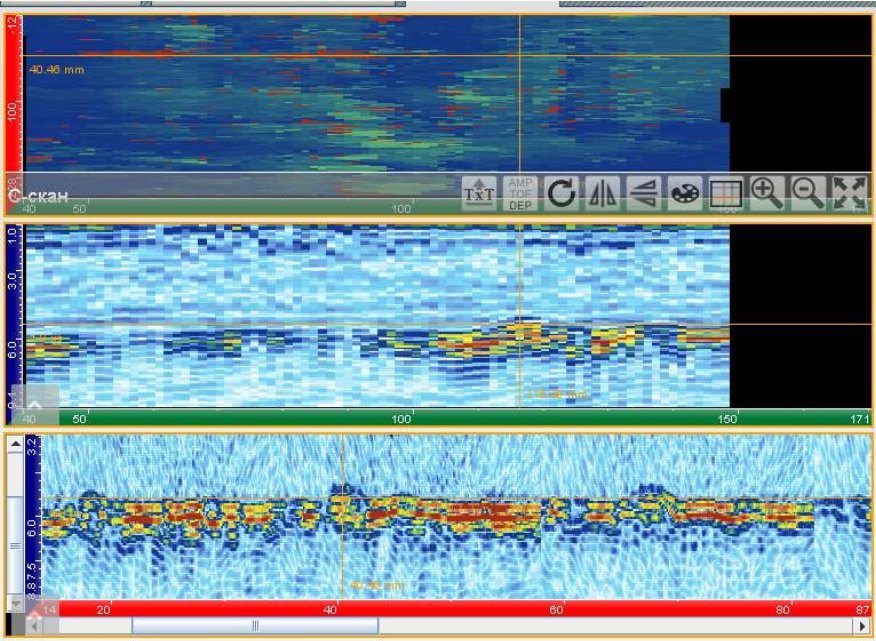

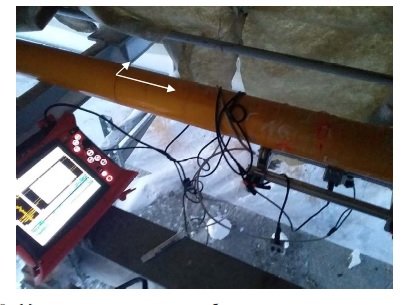

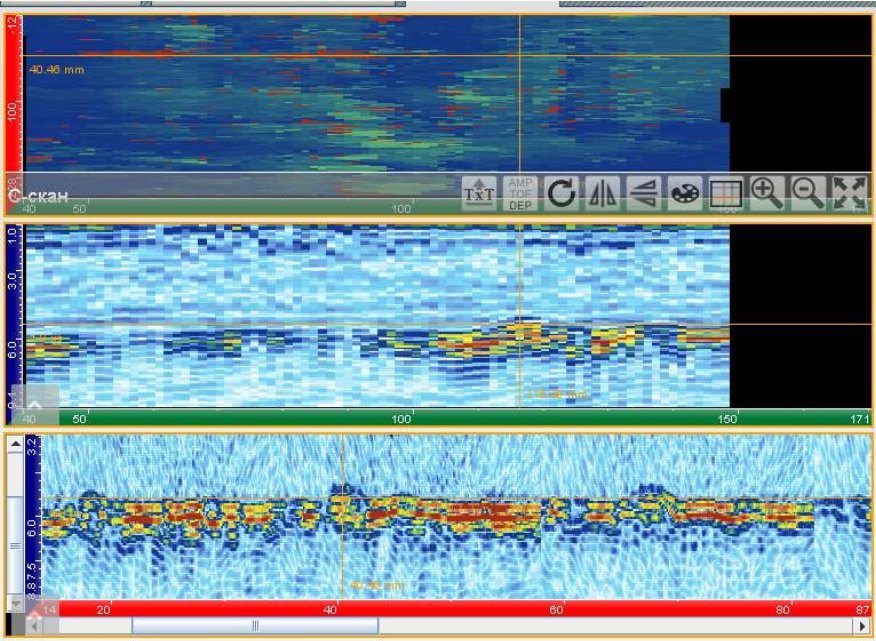

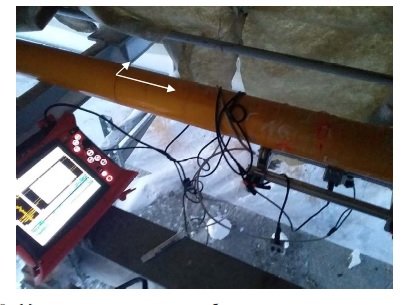

The tests were carried out at the Bovanenkovsky NGCM of Gazprom Dobycha Nadym LLC. To solve the problem of continuous thickness measurement, a GEKKO phased array flaw detector and a Chameleon two-coordinate scanner were used.

A feature of the GEKKO flaw detector is the support of the digital antenna focusing method (CFA, TFM), which allows you to obtain high-resolution cross-section images of the control object and detect small pitting corrosion (from 0.5 mm in depth, from 1-2 mm linear size).

The flaw detector supports any scanning devices for data collection with reference to the coordinate.

The CHAMELEON scanner is designed for continuous thickness measurement of straight sections of pipelines and the stretched part of bends, as well as for ultrasonic inspection of annular and longitudinal welds of pipelines from 114 mm, including the near-seam zone.

The possibility of detecting pitting corrosion (0.5 - 1 mm) in field gas pipelines is shown.

The measurements were carried out in laboratory conditions and at a temperature of minus 17 degrees.

The tests were carried out at the Bovanenkovsky NGCM of Gazprom Dobycha Nadym LLC. To solve the problem of continuous thickness measurement, a GEKKO phased array flaw detector and a Chameleon two-coordinate scanner were used.

A feature of the GEKKO flaw detector is the support of the digital antenna focusing method (CFA, TFM), which allows you to obtain high-resolution cross-section images of the control object and detect small pitting corrosion (from 0.5 mm in depth, from 1-2 mm linear size).

The flaw detector supports any scanning devices for data collection with reference to the coordinate.

The CHAMELEON scanner is designed for continuous thickness measurement of straight sections of pipelines and the stretched part of bends, as well as for ultrasonic inspection of annular and longitudinal welds of pipelines from 114 mm, including the near-seam zone.

The possibility of detecting pitting corrosion (0.5 - 1 mm) in field gas pipelines is shown.

The measurements were carried out in laboratory conditions and at a temperature of minus 17 degrees.

Date: 3 June 2021

File: pdf / 2.99 MB

Language: Russian Отчет о применении средств сплошной толщинометрии DOWNLOAD

File: pdf / 2.99 MB

Language: Russian Отчет о применении средств сплошной толщинометрии DOWNLOAD