Using the coherence coefficient to improve the image quality of reflectors during ultrasonic testing by the TOFD method

Annular welded joint of steam generator shells PGV-1000

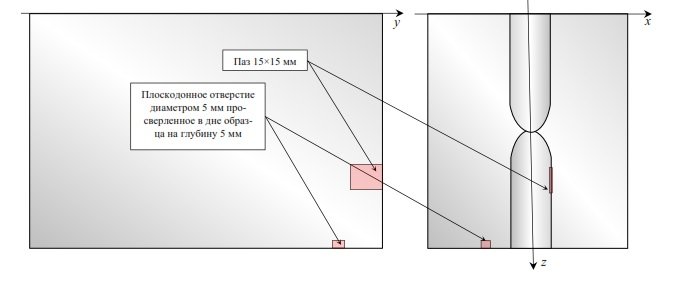

In a 145 mm thick sample made using PVG-1000 steam generator shell welding technology, the following were performed: one 0.3 mm wide lateral groove simulating a subsurface crack measuring 15×15 mm and one flat-bottomed hole with a diameter of 5 mm drilled into the bottom of the sample to a depth of 5 mm. The groove was made by electroerosion method.

Inspection results

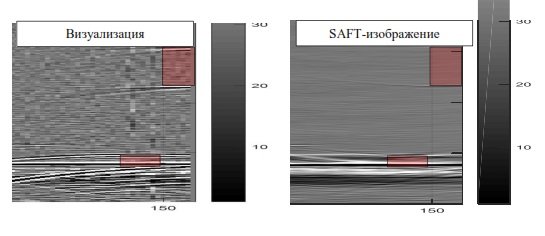

Measurements of echo signals in the Tofd mode along the axis were carried out by the AUGUR-T system with two 5 MHz converters with a plate with a diameter of 6 mm. The distance between the front faces of the converter housings was 260 mm.

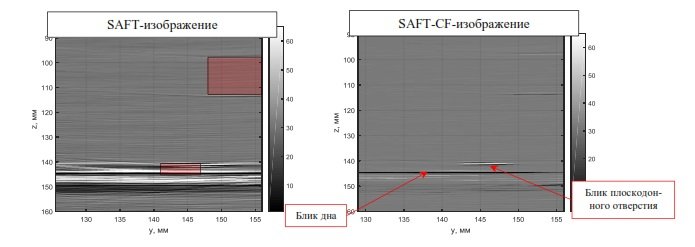

The Figure 2 on the left shows TOFD echo signals in the coordinate system of the region, and on the right - the SAFT image recovered by the frontal SAFT method. The contours of the reflectors are applied to the images with translucent rectangles. The resolution of the SAFT image has more than tripled, and the noise level has decreased by more than 6 dB. The echo signals from the flat-bottomed hole are confidently fixed in Fig. 2 on the left, although with a low resolution. In the SOFT image (Fig. 2, right) the glare of the flat-bottomed hole is masked by complex glare from the bottom of the sample, as a result of which the flat-bottomed hole may not be detected.

Obtaining CF- or SCF-images of reflectors using TOFD-echo signals allowed to obtain images of higher quality compared to the SAFT image.

File: pdf / 374.33 KB

Language: Russian Использование коэффициента когерентности для повышения качества изображения отражателей при проведении ультразвукового контроля методом TOFD DOWNLOAD