HORSE

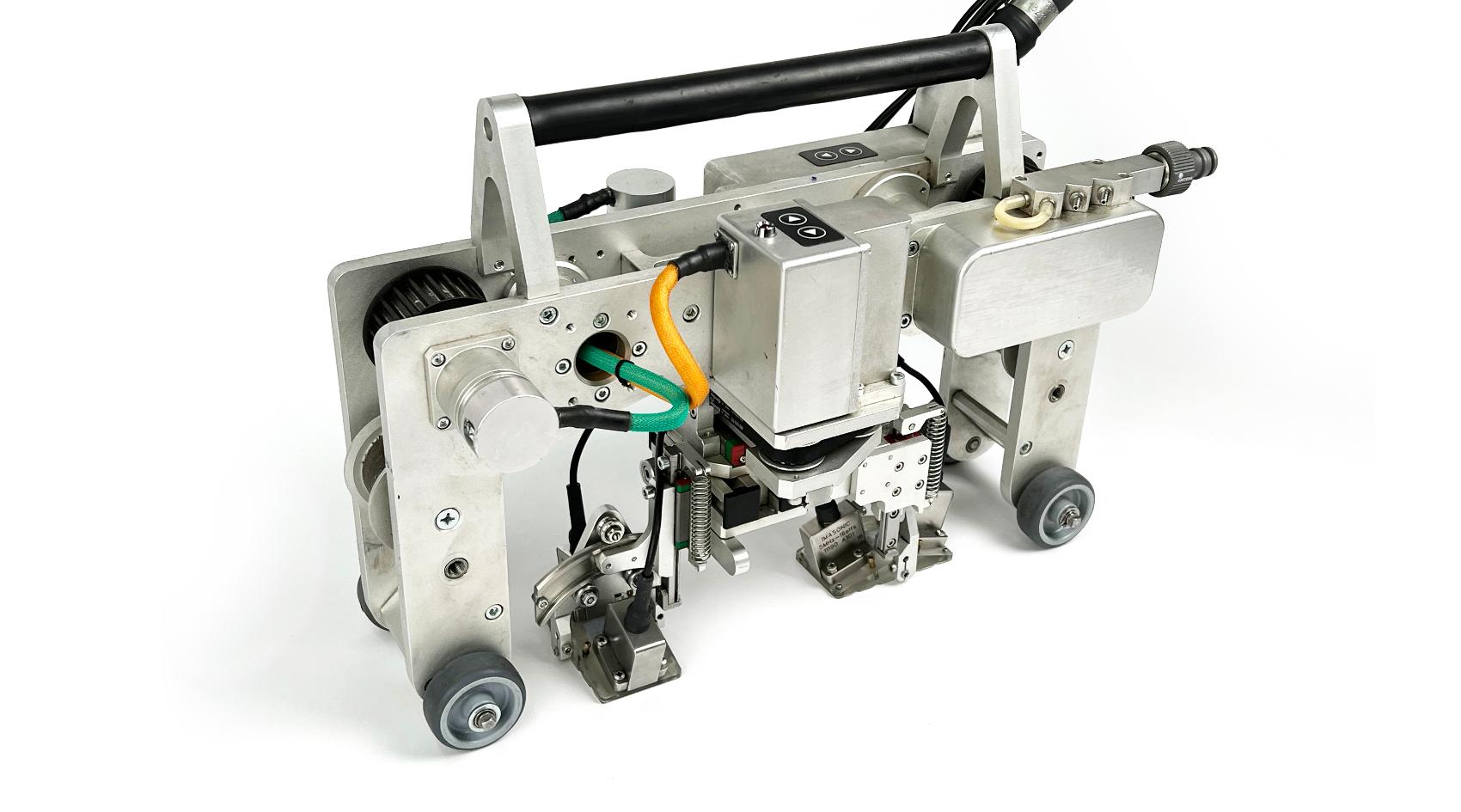

Two-axis scanner for automated inspection of welded joints with a diameter from 720 mm to 4000 mm with limited access (located in a narrow gap)

Scanner for automated control of welded joints with limited access (narrow gap), with the function of two-coordinate scanning and the ability to record data.

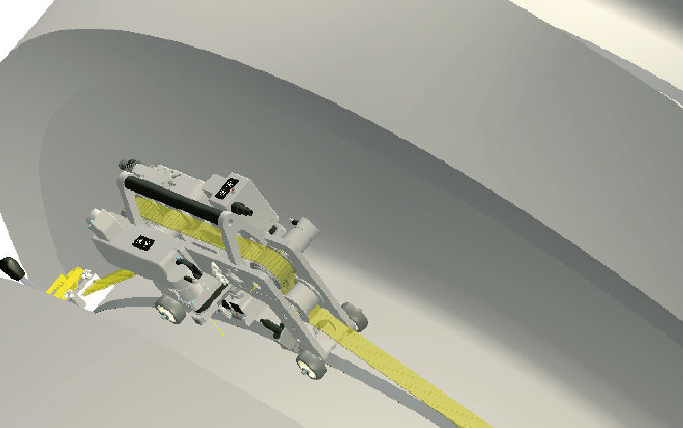

The scanner is moved along the tension belt using the scanner control device (BUSK).

Inspection with the use of a tension belt in a narrow gap.

| Name | Article | Standard equipment |

| Scanner HORSE | S0160095 |

|

Additional options

- Contact fluid supply system

- Length of cables under the order

- Converters and prisms are not included in the package and are purchased separately

- Clamps, forks and guides can be made to order

- Software for controlling the scanner from a computer

The scanner is compatible with flaw detectors:

- The August series (ECHOPLUS)

- Introvisor A1550

- MX, MX2, SX

- Harfang X-32, Veil

- Gekko

| Range of controlled pipe diameters |

from 850 and less |

| Scanning speed (high) | until 100 mm/s |

| Two-coordinate scanning in a narrow gap | until 220 mm |

| Two-coordinate scanning using phased arrays in an automated way | |

| Moving with the use of the scanner control device at a distance from the object of control | |

| Equipped with a clamp that provides optimal contact with the control surface at any position and orientation of the scanner | |

| Stainless steel housing | |

| Scanner wheels with rubber tire rings to ensure better grip on the control surfaceя | |

| The scanner is moved by a tension belt. | |

|

Dimensions, L x W x H |

458 х 200 х 302,5 mm |

|

Weight |

9,9 kg |

|

Encoder resolution on the X axis |

12,8 counts/mm |

|

Encoder resolution on the Y axis |

6.4 counts/mm |