3 February 2022

A new method of control of welded joints made according to the technology of contact butt welding by reflow

The ECHOPLUS company has developed a draft methodology for the control of welded joints made using CSR technology. In welded joints made by contact butt welding by reflow (hereinafter CSR), the most dangerous and difficult to detect defects are vertical non-melts that do not have access to any of the pipeline surfaces. The technique is based on the application of the TOFD control method (for pipelines with a thickness of 8 mm or more) and the digital focusing antenna CFA method using reflection from the pipe boundaries.

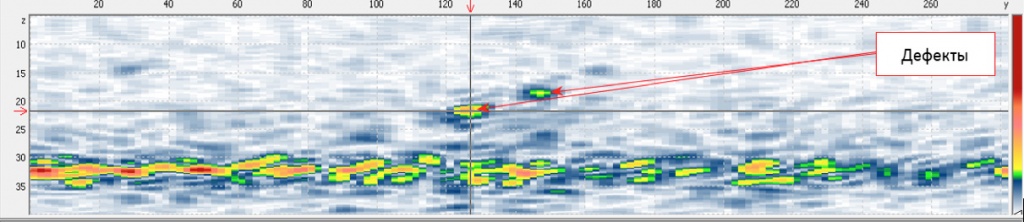

The use of the CFA method can significantly reduce the requirements for the accuracy of positioning antenna arrays relative to the axis of the welded joint and significantly reduce the time of setting up equipment for monitoring compared with the zonal focusing method. The technique was tested on samples of welded joints manufactured using CSR technology (Figure 1), on which it showed its effectiveness. Figure 2 shows the results of inspection of a sample with a welded joint made using CSR technology. The images clearly show indications of two vertical defects that do not come to the surface.

Acoustic image of a sample with a welded seam made using CSR technology containing technological defects

The proposed method of inspection of welded joints with a thickness of 8 mm, made using CSR technology, is implemented on the AUGUR-TF automated ultrasonic inspection system with a set of specialized scanning devices that provide the ability to control welded joints of pipes of various diameters (from 159 mm to a plane) and various types of equipment.

The use of the CFA method can significantly reduce the requirements for the accuracy of positioning antenna arrays relative to the axis of the welded joint and significantly reduce the time of setting up equipment for monitoring compared with the zonal focusing method. The technique was tested on samples of welded joints manufactured using CSR technology (Figure 1), on which it showed its effectiveness. Figure 2 shows the results of inspection of a sample with a welded joint made using CSR technology. The images clearly show indications of two vertical defects that do not come to the surface.

Control of a sample with a welded joint made using CSR technology

Acoustic image of a sample with a welded seam made using CSR technology containing technological defects

The proposed method of inspection of welded joints with a thickness of 8 mm, made using CSR technology, is implemented on the AUGUR-TF automated ultrasonic inspection system with a set of specialized scanning devices that provide the ability to control welded joints of pipes of various diameters (from 159 mm to a plane) and various types of equipment.